Hirotsugu Matoba

Professor, M.S. in Mechanical Engineering

- matoba.hirotsugu

- Areas of Research

- Mechanical Engineering, Production Engineering

- Profile

- Research

-

Professor Hirotsugu Matoba obtained his B.Sc. and M.Sc. degrees in Mechanical Engineering from Kyoto University in 1981 and 1983, respectively. From 1983 to 2015, he worked for Sharp Corporation and was involved in research and development of many products. In 1992 he also researched micro-electro-mechanical systems (MEMS) at the University of California, Berkeley, USA as a visiting researcher, and published several papers regarding the outcome of that research. In 2015, he was employed by Nidec, and in 2019, he joined KUAS in Kyoto, Japan, as a visiting professor.

Professor Matoba’s specialties are mechanical engineering and production engineering, and his current interests include rapid prototyping utilizing 3D-printing, laser cutting and so on.

In his spare time, Professor Matoba enjoys working out in the gym and playing with his toy poodle.

-

Development and Assessment of Innovative E-axle

-Background

In the post-COVID-19 era, the demand for personal transportation and delivery services with lower environmental impacts will grow for two reasons. First, people will shift from public transport to private vehicles in the interest of personal health safety. Secondly, consumer spending will shift from brick-and-mortar stores to online shopping. Micro-sized electric vehicles (micro EVs) about half the size of a Japanese “key” compact car and possessing energy output capacity of less than 8kW (10.7 HP) may be promising candidates to fulfill these demands.-Purpose

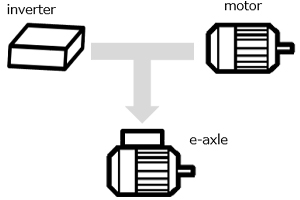

Professor Matoba, deputy director of the Nagamori Institute of Actuators, wishes to proliferate the use of micro EVs and delivery drones by developing innovative electric axles called “e-axles”. An e-axle is an integrated electrical motor and inverter. The Inverter controls the torque and rotating speed of the motor. By adopting innovative e-axles, micro EVs can be realized at a much lower cost—approximately half of those currently being produced. As for delivery drones, flight duration can be increased twofold.

-Approach

Professor Matoba plans develop his proposed e-axle through breakthrough technology adoption, industry-academia joint research and applied assessment.1.Breakthrough technology adoption:

An inverter consists of power semiconductors, capacitors and microcomputers. Power semiconductors convert the direct current (DC) of a battery to pulse current which is finally changed to alternating current (AC) in the motor. Professor Matoba will adopt silicon carbide (SiC) as a power semiconductor for the inverter. SiC is an emerging semiconductor that is two times faster than contemporary silicon (Si) solutions while possessing a breakdown voltage that is ten times higher. By replacing Si with SiC, the efficiency and power density of the inverter can be greatly boosted (theoretically, conduction losses in the transistors can be reduced a factor 100 and switching losses can also be decreased significantly). Thus, smaller, lighter, more efficient e-axles can be realized with SiC power semiconductors. For example, ROHM supplies SiC inverters that are only 60% of the size and weight of previous models utilized by the Venturi Formula E racing team. SiC power semiconductors currently cost five times more than their Si counterparts, thus their application remains limited. However, it is predicted that SiC costs will decrease drastically and SiC usage will explode over the next five years.

2. Industry-academia joint research:

To accelerate development, research work will be carried out jointly between KUAS (Dr. Alberto Castellazzi and Dr. Fuat Kucuk) and several cooperating private companies. Dr. Castellazzi will develop SiC power semiconductor modules with multi-level switching in a card-shaped package, which will then be fabricated by a partner company. Another company will then manufacture the inverters using said modules. Meanwhile, the collaborating researchers will develop motors co-designed in parallel with the inverters.3. Applied assessment:

The performance and reliability of the developed e-axle will be verified by mounting it on a commercially available micro EV, the TAJIMA JIAYUAN. The superior range, or electric gas mileage, of the vehicle will be demonstrated on a test course and on the road.

-Goal

The goal of this research will be to develop a revolutionary e-axle using SiC power semiconductor through industry-academia partnerships and real-life performance assessments. The elemental technology that results will be deployed not only to micro EVs but also to drones in the future. Using this technology, Professor Matoba’s ultimate goal is to create air vehicles for personal transportation and delivery. In addition to e-axle development, Professor Matoba also wishes to use these micro EVs for feasibility studies of mobility sharing services, information provision services and health care services, and he welcomes KUAS students who are interested in these and similar areas of research. Interested students are welcome to stop by Professor Matoba’s office.