Ryosuke Matsumoto

Professor, Ph.D. in Engineering

- matsumoto.ryosuke

- Areas of Research

- Solid Mechanics, Computational Mechanics, Strength and Fracture of Materials, Atomic Level Simulation

- Profile

- Research

-

Dr. Ryosuke Matsumoto obtained his M.Sc. and Ph.D. in Engineering from Osaka University in 2000 and 2003, respectively. He has continuously worked in academia, including Osaka University, Kyushu Institute of Technology and Kyoto University. He also experienced a short stint at the University of Stuttgart. He worked in the solid mechanics field under the support of numerous research grants. With his outstanding achievements, he has already received more than ten academic awards including international awards such as the APACM Award for Young Investigators in Computational Mechanics.

Dr. Matsumoto’s main research topic is hydrogen effect on material strength. Since hydrogen degrades the strength of almost all materials, the hydrogen related fracture phenomena are found in traditional offshore structures, chemical plants and recent machine systems made of high strength steels and advanced equipment for hydrogen energy society. He is tackling this big engineering issue by using advanced computational simulations and experimental techniques to acquire the guiding principle for designing safety machines and developing hydrogen-resistant materials.

Dr. Matsumoto is in charge of the Mechanics of Materials course at KUAS Faculty of Engineering and also oversees some engineering physics and mathematics courses. He is excited to take up the challenge of sparking innovation in education at KUAS.

Outside academia, Dr. Matsumoto enjoys cycling together with his wife and teammates from a variety of backgrounds. He previously participated in the Japan Cycling Championships through intensive and strategic training. He also enjoys fishing and outdoor activities.

-

Understanding and Controlling Defects in Materials

Materials are used to support structures and join components at various scales, from massive infrastructures to tiny devices. However, damage to or destruction of those structures can lead to injury or death if not properly prevented. Even if structural damage does not endanger human life, it can have economic impacts to a greater or lesser extent. We all know that materials eventually break when subjected to large forces or repeated deformation, but what happens in a material during this process, and how do we determine the conditions under which said material breaks? The key to more accurate predictions of material behavior and the development of better materials is to understand what is happening inside of them.

Zooming in on a material that appears to be homogeneous reveals a hierarchy of structures and discrete properties. Metallic materials usually have a crystalline structure. When one hears the word “crystal,” they may imagine that their atoms are lined up in an orderly fashion, but in reality, crystals contain a myriad of structures called lattice defects, which are disordered arrangements of atoms. When a material is put under stress, these defects move and interact with each other, multiplying or disappearing to form a heterogeneous and complex structure. These defects can damage or destroy a material, but they can also impart exceptional strength and toughness by moderately constraining each other’s motion.

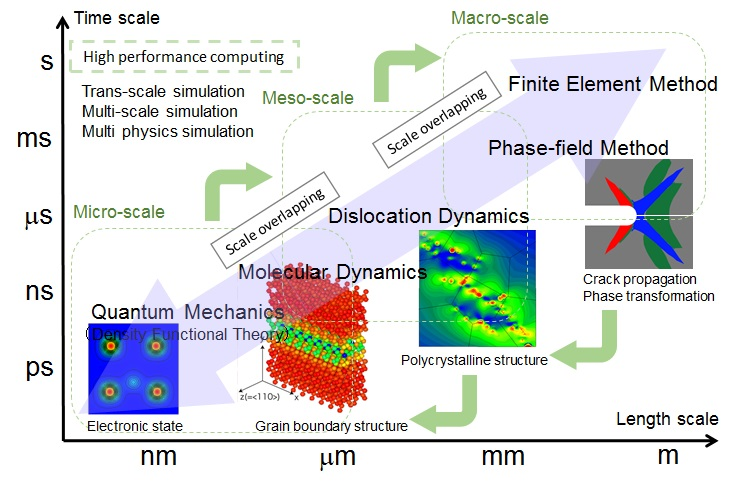

The research theme of the Material Mechanics Laboratory is “understanding, controlling, and exploiting defects”. This lab mainly uses atomistic simulations, but also more microscopic electron-level calculations (first-principles calculations) and as well as more macroscopic simulation methods, sometimes combining them to study metal deformation from a microscopic viewpoint. Currently, the Material Mechanics Laboratory is working on (i) hydrogen embrittlement and (ii) deformation behavior of magnesium alloys. Here is a brief introduction to the former.

Hydrogen embrittlement is a phenomenon in which the strength of a metal is greatly degraded when hydrogen enters the metal during the manufacturing process or in the operating environment. This phenomenon is called Hydrogen Embrittlement (HE). The development of fuel cell vehicles and other devices is underway due to environmental concerns, and the number of fracture accidents caused by HE will surely increase as a result. The main goal of the Material Mechanics Laboratory’s research is to clarify the causes of HE, which will be useful for material development and design. The strength loss due to hydrogen is attributed to the fact that hydrogen acts on lattice defects and negatively changes their behavior. Therefore, the Material Mechanics Laboratory predicts the distribution of hydrogen around various lattice defects based on atomistic simulations and analyzes in detail the effects of hydrogen on the motion and interaction behavior of lattice defects to unravel the effects of hydrogen one by one from a microscopic viewpoint.